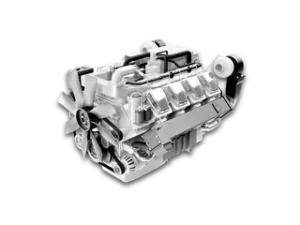

Air brake systems are essential for the safe operation of heavy-duty vehicles such as trucks and buses. At the heart of these systems lies the air brake compressor, a critical component that ensures consistent air pressure for optimal braking performance. Cummins air brake compressors are renowned for their reliability, durability, and advanced engineering, making them a preferred choice in the commercial vehicle industry.

What Are Air Brake Compressors and How Do They Work?

Air brake compressors generate and maintain the air pressure required to operate a vehicle’s braking system. Powered by the engine, these compressors draw in atmospheric air, compress it, and deliver it to the air storage tanks. This compressed air is then used to activate the brake chambers, ensuring smooth and efficient stopping power.

Cummins air brake compressors are designed to handle heavy workloads, ensuring consistent performance even in demanding conditions. Their robust construction and high efficiency make them indispensable for heavy-duty vehicles.

Benefits of Using Cummins Air Brake Compressors

Cummins air brake compressors stand out in the industry due to their exceptional reliability, efficiency, and durability, making them indispensable for heavy-duty vehicles. Their robust design ensures consistent performance, even under demanding conditions, providing peace of mind for operators. One of the primary benefits is their ability to optimize air generation with advanced engineering, which not only enhances braking efficiency but also reduces fuel consumption, contributing to overall operational cost savings. Additionally, Cummins compressors are built with high-quality materials that minimize wear and tear, resulting in extended service life and lower maintenance requirements. These features make them a valuable investment for fleet operators aiming to ensure safety and reduce downtime, ultimately boosting productivity and profitability.

Common Issues and Maintenance Tips for Air Brake Compressors

Regular maintenance is crucial to ensure the smooth operation of air brake compressors. Here are some common issues and tips for maintaining Cummins air brake compressors:

- Air Leaks: Regularly inspect air lines and connections to prevent air leaks that can compromise braking efficiency.

- Oil Contamination: Ensure proper lubrication and monitor for oil contamination in the air system, as it can damage components.

- Overheating: Maintain adequate cooling and clean filters to prevent overheating, which can reduce the lifespan of the compressor.

Why Choose Cummins Air Brake Compressors for Your Fleet?

Cummins air brake compressors are trusted by fleet operators worldwide for their unmatched performance and dependability. Whether you’re looking to enhance safety, improve operational efficiency, or reduce maintenance costs, Cummins compressors deliver exceptional value.

Cummins air brake compressors play a vital role in ensuring the safety and efficiency of heavy-duty vehicles. Their reliability and performance make them a top choice for operators seeking to enhance their fleet’s braking systems. For high-quality Cummins air brake compressors and other automotive spare parts, visit Aspatech Automotive today and explore our comprehensive product range.

Frequently Asked Questions (FAQ)

What makes Cummins air brake compressors different from other brands?

Cummins air brake compressors are known for their innovative design, robust construction, and exceptional reliability, making them ideal for heavy-duty applications.

How often should I service my air brake compressor?

It is recommended to follow the manufacturer’s guidelines, typically servicing the compressor every 50,000 to 100,000 miles, depending on usage and operating conditions.

Can I use a Cummins air brake compressor on non-Cummins engines?

Yes, many Cummins compressors are compatible with various engine models. Consult the product specifications or a professional to ensure proper fitment.

What are the signs of a failing air brake compressor?

Common signs include reduced braking efficiency, unusual noises, overheating, and visible oil leaks.

How do I increase the lifespan of my air brake compressor?

Regular maintenance, proper lubrication, and timely replacement of worn-out parts can significantly extend the life of your air brake compressor.